Powered by Carbon AI, LaserWeeder G2 provides farmers with precise weed control in new sizes, configurations and prices.

The post Carbon Robotics’ LaserWeeder G2 destroys weeds even faster appeared first on The Robot Report.

Carbon Robotics launched the second generation of its laser weeding product. The LaserWeeder G2 is designed to be faster, lighter, and more power-efficient than its predecessor. The system uses vision-targeted lasers to destroy weed plants as they emerge from the soil. The onboard vision cameras and AI-based perception model discriminate between crop plants, beneficial plants, and weed plants, targeting the laser at the weed plants.

The company said laser weeding has a payback period of 1-3 years for equipment that has a lifetime of 7-10 years. The business case for laser weeding is twofold: manual labor savings and herbicide chemical reduction. The company claims the G2 units are twice as fast as the earlier generation.

The company closed a $70M funding round in October 2024 and celebrated a milestone of killing 10B weeds. The 2024 funding rounds gave the company the necessary capital to ramp up production, sales, and support for the solution.

“At Tanimura & Antle, we have a long history of implementing cutting-edge innovations throughout our operations in order to drive efficiency, advance sustainability, and produce the premium quality fresh produce our customers expect,” said Scott Rossi, vice president of northern farming operations at Tanimura & Antle. “The LaserWeeder G2 is another game-changing technology that we have been implementing in our commitment to innovation. By integrating this precision technology into our operations, we are taking another step forward in reducing labor costs, optimizing resources, and continuing our legacy of innovation in the industry.”

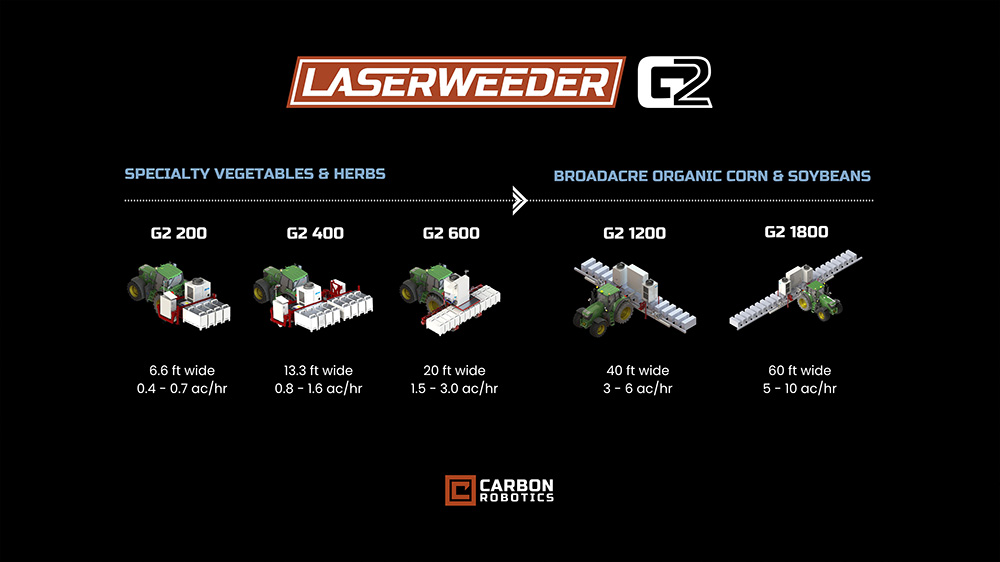

The G2 product family offers five product configurations, built around the newly redesigned core power and processing unit. Check out the image below to quickly compare the models. The lightest implement starts at 1,930 kg (4,250 pounds), enabling it to be pulled by smaller and lighter tractors, while the 6-meter (20 ft) version is 25% lighter than the original LaserWeeder. Additionally, its modular design supports machine widths ranging from 6.6 to 60 feet, offering flexible configurations to fit diverse farm requirements and budgets.

The LaserWeeder G2 is now available in five different configurations, optimized for two types of crops. | Credit: Carbon Robotics

<!–

Specialty Vegetable Crops and Herb Models

LaserWeeder G2 200

Width: 2.0 meters (6.6 feet)

Weight: 1,928 kilograms (4,250 pounds)

Description: Ideal for smaller farms, its compact size makes it easier to transport.

LaserWeeder G2 400

Width: 4.0 meters (13.3 feet)

Weight: 2,722 kilograms (6,000 pounds)

Description: A versatile mid-size model capable of handling diverse crop types and field layouts.

LaserWeeder G2 600

Width: 6.1 meters (20 feet)

Weight: 3,266 kilograms (7,200 pounds)

Description: The next generation of Carbon Robotics’ industry-leading LaserWeeder, designed for a wide range of specialty vegetable and herb crops.

Broadacre Organic Corn and Soybean Models

LaserWeeder G2 1200

Width: 12.2 meters (40 feet)

Weight: 5,443 kilograms (12,000 pounds)

Description: Specifically designed for organic corn and soybean operations, this model introduces the first broadacre weeding solution that does not disturb crops or soil, significantly increasing yields.

LaserWeeder G2 1800

Width: 18.3 meters (60 feet)

Weight: 6,350 kilograms (14,000 pounds)

Description: Built for large-scale organic corn and soybean operations, it integrates seamlessly with farming operations standardized on 60-foot-wide farming equipment.–>

LaserWeeder G2 a new hardware platform

With the G2 platform, the company completely redesigned the hardware to make it more robust, power-efficient, and faster at identifying weeds and targeting the lasers. To achieve this, the G2 uses the latest NVIDIA processors, improved lasers, perception cameras, and lighting. The units are also equipped with a Starlink satellite antenna for high bandwidth connection to the cloud.

“LaserWeeder G2 is a huge leap forward. Designed with Carbon AI, the new product line benefits from years of learning in real-world farm fields and conditions,” said Paul Mikesell, CEO and founder of Carbon Robotics. “All of the hardware components are upgraded. This was an incredible feat by our world-class engineering, product, and field teams. I’m extremely proud of this new technology and how it will help farmers set a new standard in farm profitability and sustainability.”

Powered by Carbon AI, an advanced deep learning system for plant detection and identification, the LaserWeeder G2 utilizes a growing dataset of over 40 million plants labeled from three continents. The operator interface for the smart implement is accessible via an app on a tablet or smartphone. The G2 version is twice as fast at processing and killing weeds, enabling faster operation.

Register today to save 40% on conference passes!

The post Carbon Robotics’ LaserWeeder G2 destroys weeds even faster appeared first on The Robot Report.

Carbon Robotics launched the second generation of its laser weeding product. The LaserWeeder G2 is designed to be faster, lighter, and more power-efficient than its predecessor. The system uses vision-targeted lasers to destroy weed plants as they emerge from the soil. The onboard vision cameras and AI-based perception model discriminate between crop plants, beneficial plants, and weed plants, targeting the laser at the weed plants.

The company said laser weeding has a payback period of 1-3 years for equipment that has a lifetime of 7-10 years. The business case for laser weeding is twofold: manual labor savings and herbicide chemical reduction. The company claims the G2 units are twice as fast as the earlier generation.

The company closed a $70M funding round in October 2024 and celebrated a milestone of killing 10B weeds. The 2024 funding rounds gave the company the necessary capital to ramp up production, sales, and support for the solution.

“At Tanimura & Antle, we have a long history of implementing cutting-edge innovations throughout our operations in order to drive efficiency, advance sustainability, and produce the premium quality fresh produce our customers expect,” said Scott Rossi, vice president of northern farming operations at Tanimura & Antle. “The LaserWeeder G2 is another game-changing technology that we have been implementing in our commitment to innovation. By integrating this precision technology into our operations, we are taking another step forward in reducing labor costs, optimizing resources, and continuing our legacy of innovation in the industry.”

The G2 product family offers five product configurations, built around the newly redesigned core power and processing unit. Check out the image below to quickly compare the models. The lightest implement starts at 1,930 kg (4,250 pounds), enabling it to be pulled by smaller and lighter tractors, while the 6-meter (20 ft) version is 25% lighter than the original LaserWeeder. Additionally, its modular design supports machine widths ranging from 6.6 to 60 feet, offering flexible configurations to fit diverse farm requirements and budgets.

The LaserWeeder G2 is now available in five different configurations, optimized for two types of crops. | Credit: Carbon Robotics

<!–

Specialty Vegetable Crops and Herb Models

LaserWeeder G2 200

Width: 2.0 meters (6.6 feet)

Weight: 1,928 kilograms (4,250 pounds)

Description: Ideal for smaller farms, its compact size makes it easier to transport.

LaserWeeder G2 400

Width: 4.0 meters (13.3 feet)

Weight: 2,722 kilograms (6,000 pounds)

Description: A versatile mid-size model capable of handling diverse crop types and field layouts.

LaserWeeder G2 600

Width: 6.1 meters (20 feet)

Weight: 3,266 kilograms (7,200 pounds)

Description: The next generation of Carbon Robotics’ industry-leading LaserWeeder, designed for a wide range of specialty vegetable and herb crops.

Broadacre Organic Corn and Soybean Models

LaserWeeder G2 1200

Width: 12.2 meters (40 feet)

Weight: 5,443 kilograms (12,000 pounds)

Description: Specifically designed for organic corn and soybean operations, this model introduces the first broadacre weeding solution that does not disturb crops or soil, significantly increasing yields.

LaserWeeder G2 1800

Width: 18.3 meters (60 feet)

Weight: 6,350 kilograms (14,000 pounds)

Description: Built for large-scale organic corn and soybean operations, it integrates seamlessly with farming operations standardized on 60-foot-wide farming equipment.–>

LaserWeeder G2 a new hardware platform

With the G2 platform, the company completely redesigned the hardware to make it more robust, power-efficient, and faster at identifying weeds and targeting the lasers. To achieve this, the G2 uses the latest NVIDIA processors, improved lasers, perception cameras, and lighting. The units are also equipped with a Starlink satellite antenna for high bandwidth connection to the cloud.

“LaserWeeder G2 is a huge leap forward. Designed with Carbon AI, the new product line benefits from years of learning in real-world farm fields and conditions,” said Paul Mikesell, CEO and founder of Carbon Robotics. “All of the hardware components are upgraded. This was an incredible feat by our world-class engineering, product, and field teams. I’m extremely proud of this new technology and how it will help farmers set a new standard in farm profitability and sustainability.”

Powered by Carbon AI, an advanced deep learning system for plant detection and identification, the LaserWeeder G2 utilizes a growing dataset of over 40 million plants labeled from three continents. The operator interface for the smart implement is accessible via an app on a tablet or smartphone. The G2 version is twice as fast at processing and killing weeds, enabling faster operation.

Register today to save 40% on conference passes!

The post Carbon Robotics’ LaserWeeder G2 destroys weeds even faster appeared first on The Robot Report.