Last year, AMP announced deployments in North Carolina and Virginia. It ended the year by raising $91 million in funding.

The post AMP CEO shares insights into the company’s waste sortation strategy appeared first on The Robot Report.

2024 marked a period of change for AMP Robotics Corp. The company started the year by dropping the “robotics” from its name to highlight its expanded portfolio of offerings. Later in the year, it welcomed Tim Stuart, the former chief operating officer of Republic Services Inc., as its new CEO.

These changes, however, didn’t slow AMP’s progress. It also announced deployments in North Carolina and Virginia. The Louisville, Colo.-based company ended the year by raising $91 million in funding.

In Virginia, the company’s AMP One system processes 150 tons of municipal solid waste (MSW) per day. The system extracts mixed recyclables and organic material from the MSW. AMP said the system is operating at over 90% uptime.

Tim Stuart sat down with The Robot Report to give insight into the company’s technology and his time at AMP.

Register today to save 40% on conference passes!

AMP plans to become an operating company

Stuart came to AMP with extensive experience in the waste industry.

“I had the fortunate chance of coming into the waste space a couple of years out of undergrad with WM [Waste Management Inc.] and in a management training program,” he said. “I got the opportunity to move to different locations and take on increasing responsibility. I moved over to Republic after about 11 years at WM and did the same thing.”

Eventually, Stuart became chief operating officer of Republic, where he was in charge of 40,000 employees, $15 billion in revenue, and 550 locations across the U.S. and Canada.

“I had known AMP because, obviously, Republic had run recycling facilities,” he recalled. “We had purchased and used their robots to make us more effective and efficient on recycling sortation lines.”

Stuart said his experience working for companies that were traditionally AMP’s customers will help moving forward.

“We are turning into more of an operating company,” he said. “So, we’re going to take this technology and partner with other companies or municipalities to operate their facilities.”

“I think I have a unique perspective to make sure that we’re injecting this in the right place at the right time and with the right partners going forward,” Stuart continued.

AMP’s goal is to divert more waste from landfills by ensuring the removal of more recyclables and organics out of the waste stream.

Inside AMP’s AI and technology

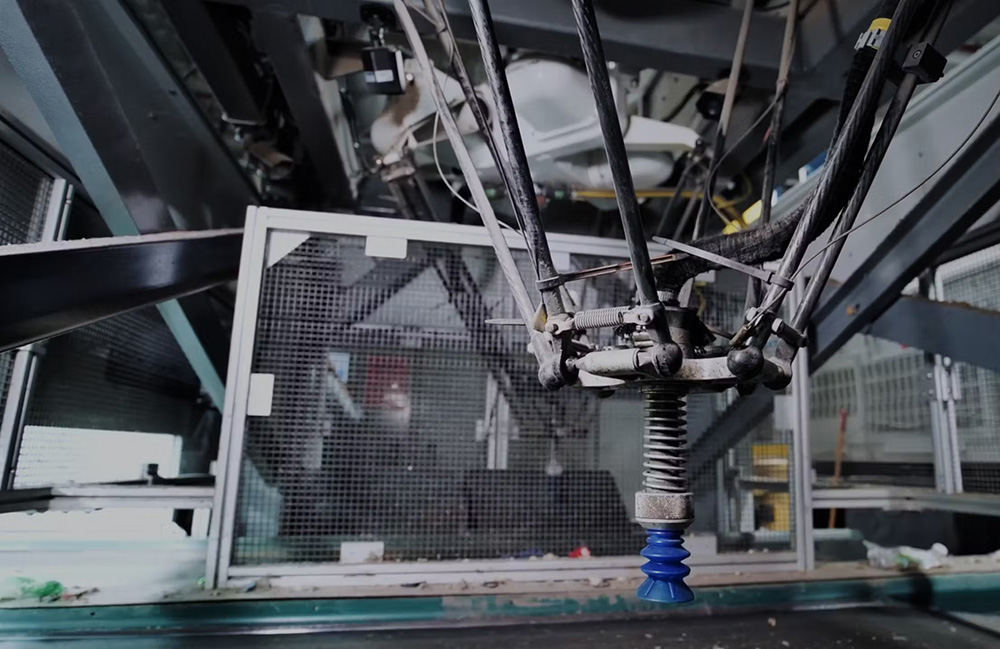

While AMP has dropped “robotics” from its name, that doesn’t mean the company stopped using the technology.

“We’re going to continue to build robots and use our business systems to set up these sortation lines for municipalities or for the big waste haulers, like waste connection,” Stuart said. “We’re also going to go a little more aggressive on that MSW side of things, and we’re working on our first big deal there. We hope to make it public in Q1.”

“The AI, the technology, and the robots have been an integral part of AMP for the last 10 years, and I think the team has stayed abreast and actually pushed forward on a lot of that,” he added. “Most of the energy early on was focused on making the sortation line more effective and efficient. What you’ll see going forward is that we’ll continue to always be more effective and efficient, but we’ll grow outside of the sortation line.”

This includes understanding and being able to pick anything that comes through the line, which requires advanced AI. AMP is working to build all of its technology in-house.

“The technology is homegrown, I think we have 60 or 70 patents over the years that Matanya [Horowitz] and his engineering team have built and put into practice,” said Stuart. “The brains are all AMP, and we build some aspects of the equipment. But we also go procure some other parts of it to really put that whole sortation line in.”

What’s limiting the robotic waste sortation market?

While AMP is working around the clock to advance sortation technology in waste management, there are still limitations holding back adoption.

“It hasn’t happened because the technology has not been there, and the cost associated with doing this was too high to really have a solution,” Stuart said. “So the AMP team has built this technology, we’ve had it deployed in Virginia for about a year, testing and doing R&D on it, and it’s ready for prime time now.”

Much of the waste sortation industry has been investing in automating different processes, he noted.

“I think the industry has been more focused on the mechanics on the hauling side, the trucks, and the equipment associated,” Stuart said. “We are trying to take that and move that technology, or that importance, to what we do in MSW.”

Even with these limitations, Stuart sees a lot of potential for the robotics and automation improving sustainability.

“We believe that we can have a huge impact on the environment, and change that equation to really reduce up to 60% of the material going to the landfill. That is a massive game changer for the industry.”

The post AMP CEO shares insights into the company’s waste sortation strategy appeared first on The Robot Report.

2024 marked a period of change for AMP Robotics Corp. The company started the year by dropping the “robotics” from its name to highlight its expanded portfolio of offerings. Later in the year, it welcomed Tim Stuart, the former chief operating officer of Republic Services Inc., as its new CEO.

These changes, however, didn’t slow AMP’s progress. It also announced deployments in North Carolina and Virginia. The Louisville, Colo.-based company ended the year by raising $91 million in funding.

In Virginia, the company’s AMP One system processes 150 tons of municipal solid waste (MSW) per day. The system extracts mixed recyclables and organic material from the MSW. AMP said the system is operating at over 90% uptime.

Tim Stuart sat down with The Robot Report to give insight into the company’s technology and his time at AMP.

Register today to save 40% on conference passes!

AMP plans to become an operating company

Stuart came to AMP with extensive experience in the waste industry.

“I had the fortunate chance of coming into the waste space a couple of years out of undergrad with WM [Waste Management Inc.] and in a management training program,” he said. “I got the opportunity to move to different locations and take on increasing responsibility. I moved over to Republic after about 11 years at WM and did the same thing.”

Eventually, Stuart became chief operating officer of Republic, where he was in charge of 40,000 employees, $15 billion in revenue, and 550 locations across the U.S. and Canada.

“I had known AMP because, obviously, Republic had run recycling facilities,” he recalled. “We had purchased and used their robots to make us more effective and efficient on recycling sortation lines.”

Stuart said his experience working for companies that were traditionally AMP’s customers will help moving forward.

“We are turning into more of an operating company,” he said. “So, we’re going to take this technology and partner with other companies or municipalities to operate their facilities.”

“I think I have a unique perspective to make sure that we’re injecting this in the right place at the right time and with the right partners going forward,” Stuart continued.

AMP’s goal is to divert more waste from landfills by ensuring the removal of more recyclables and organics out of the waste stream.

Inside AMP’s AI and technology

While AMP has dropped “robotics” from its name, that doesn’t mean the company stopped using the technology.

“We’re going to continue to build robots and use our business systems to set up these sortation lines for municipalities or for the big waste haulers, like waste connection,” Stuart said. “We’re also going to go a little more aggressive on that MSW side of things, and we’re working on our first big deal there. We hope to make it public in Q1.”

“The AI, the technology, and the robots have been an integral part of AMP for the last 10 years, and I think the team has stayed abreast and actually pushed forward on a lot of that,” he added. “Most of the energy early on was focused on making the sortation line more effective and efficient. What you’ll see going forward is that we’ll continue to always be more effective and efficient, but we’ll grow outside of the sortation line.”

This includes understanding and being able to pick anything that comes through the line, which requires advanced AI. AMP is working to build all of its technology in-house.

“The technology is homegrown, I think we have 60 or 70 patents over the years that Matanya [Horowitz] and his engineering team have built and put into practice,” said Stuart. “The brains are all AMP, and we build some aspects of the equipment. But we also go procure some other parts of it to really put that whole sortation line in.”

What’s limiting the robotic waste sortation market?

While AMP is working around the clock to advance sortation technology in waste management, there are still limitations holding back adoption.

“It hasn’t happened because the technology has not been there, and the cost associated with doing this was too high to really have a solution,” Stuart said. “So the AMP team has built this technology, we’ve had it deployed in Virginia for about a year, testing and doing R&D on it, and it’s ready for prime time now.”

Much of the waste sortation industry has been investing in automating different processes, he noted.

“I think the industry has been more focused on the mechanics on the hauling side, the trucks, and the equipment associated,” Stuart said. “We are trying to take that and move that technology, or that importance, to what we do in MSW.”

Even with these limitations, Stuart sees a lot of potential for the robotics and automation improving sustainability.

“We believe that we can have a huge impact on the environment, and change that equation to really reduce up to 60% of the material going to the landfill. That is a massive game changer for the industry.”

The post AMP CEO shares insights into the company’s waste sortation strategy appeared first on The Robot Report.