Mytra’s CTO Ahmad Baitalmal shares why he believes robots should focus on function above a familiar design.

The post Why the future of robotics isn’t necessarily humanoid appeared first on The Robot Report.

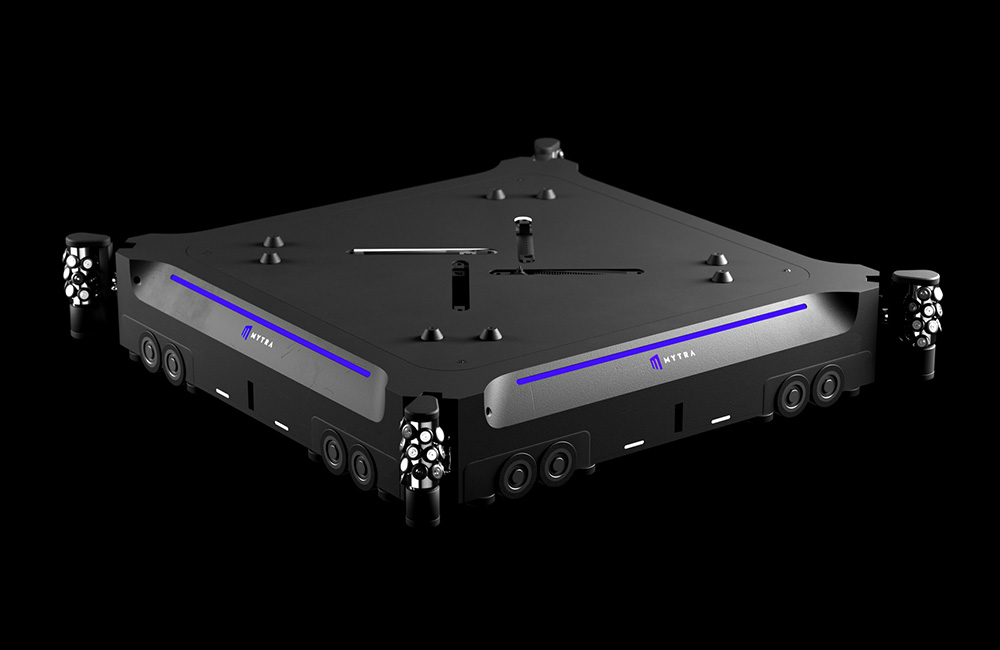

Mytra offers a pallet-sized automated storage and retrieval system to move inventory in any direction. | Source: Mytra

The robotics industry has long been captivated by the idea of humanoid robots—machines that mimic human appearance and movement. While this vision aligns with science fiction, it’s not necessarily the best approach for solving real-world automation challenges. In warehouse and logistics operations, where the goal is to transport massive pallets, navigate tight spaces, and optimize throughput, efficiency must take precedence over anthropomorphism.

Just as evolution optimizes lifeforms to survive in their environments, robotics should be designed based on function, not familiarity for familiarity’s sake. Nature doesn’t force every species into a human shape—birds evolved for flight, cheetahs for speed, etc. There is a reason why airplanes, windmills, or even cars look and work the way they do. They are optimized to perform a particular task.

Similarly, robots should be designed to solve problems in the most effective way possible, rather than being constrained by the limitations of human-like movement. The industry’s biggest challenges aren’t being solved by humanoid robots. They’re being solved by machines purpose-built to optimize movement, storage, and material flow.

Engineer for efficiency, not humanoid imitation

The fundamental question in robotics should always be: “What is the most efficient and reliable form for a given task?”

In warehouse automation, for example, lifting and transporting thousands of pounds of material is the priority. That’s why robotic arms, autonomous mobile robots (AMRs), and automated storage and retrieval systems (ASRS) have become the industry standard—not bipedal robots attempting to replicate human labor.

This distinction is more than just a theoretical debate; it has real implications for how companies scale their automated systems moving forward. Humanoid robotics are in their early stage and still face major hurdles in dexterity, balance, and power efficiency that make them impractical for most industrial applications.

The investments in humanoid robotics will likely yield many positive technical advancements in the long term, so they should keep coming. Meanwhile, purpose-built robotic systems are already driving efficiency gains across warehouses and supply chains.

Register today to save 40% on conference passes!

Unlock new capabilities rather than recreate old ones

The real promise of robotics isn’t in making machines that look like us—it’s in making previously impossible tasks feasible. For example, modern AI-powered vision systems enable robots to track and manage inventory more accurately than humans ever could.

Advanced automation allows warehouses to store more products in smaller footprints, reducing overhead costs and improving logistics efficiency. These innovations wouldn’t be possible if we insisted on designing robots to work like humans rather than working from a blank slate and letting form follow function.

At Mytra, we focus on creating robotics that make material handling and storage dramatically more efficient. Our technology isn’t built to replace humans—it’s built to augment human capabilities and optimize workflows that were previously constrained by manual labor.

The future of robotics isn’t about waiting for humanoids to develop enough to replace workers decades from now; it’s about solving today’s problems with the best tools available.

Rethink the future of robotics

As automation continues to reshape industries, the most successful robots will be those that break free from the constraints of human form and instead focus on solving real-world challenges with the right design. Just as evolution rewards adaptability and function, robotics should follow the same principles—creating purpose-built systems that maximize efficiency, scalability, and reliability.

The future of robotics lies in engineering solutions that work now, not decades from now. The warehouses of tomorrow won’t be run by human-shaped robots; they’ll be powered by automation that’s purpose-built for the task at hand and makes the impossible possible.

About the author

About the author

Ahmad Baitalmal is co-founder and chief technology officer of South San Francisco-based Mytra. He has more than 25 years of experience leading the development of large-scale enterprise systems at companies such as Tesla and Rivian.

The post Why the future of robotics isn’t necessarily humanoid appeared first on The Robot Report.

Mytra offers a pallet-sized automated storage and retrieval system to move inventory in any direction. | Source: Mytra

The robotics industry has long been captivated by the idea of humanoid robots—machines that mimic human appearance and movement. While this vision aligns with science fiction, it’s not necessarily the best approach for solving real-world automation challenges. In warehouse and logistics operations, where the goal is to transport massive pallets, navigate tight spaces, and optimize throughput, efficiency must take precedence over anthropomorphism.

Just as evolution optimizes lifeforms to survive in their environments, robotics should be designed based on function, not familiarity for familiarity’s sake. Nature doesn’t force every species into a human shape—birds evolved for flight, cheetahs for speed, etc. There is a reason why airplanes, windmills, or even cars look and work the way they do. They are optimized to perform a particular task.

Similarly, robots should be designed to solve problems in the most effective way possible, rather than being constrained by the limitations of human-like movement. The industry’s biggest challenges aren’t being solved by humanoid robots. They’re being solved by machines purpose-built to optimize movement, storage, and material flow.

Engineer for efficiency, not humanoid imitation

The fundamental question in robotics should always be: “What is the most efficient and reliable form for a given task?”

In warehouse automation, for example, lifting and transporting thousands of pounds of material is the priority. That’s why robotic arms, autonomous mobile robots (AMRs), and automated storage and retrieval systems (ASRS) have become the industry standard—not bipedal robots attempting to replicate human labor.

This distinction is more than just a theoretical debate; it has real implications for how companies scale their automated systems moving forward. Humanoid robotics are in their early stage and still face major hurdles in dexterity, balance, and power efficiency that make them impractical for most industrial applications.

The investments in humanoid robotics will likely yield many positive technical advancements in the long term, so they should keep coming. Meanwhile, purpose-built robotic systems are already driving efficiency gains across warehouses and supply chains.

Register today to save 40% on conference passes!

Unlock new capabilities rather than recreate old ones

The real promise of robotics isn’t in making machines that look like us—it’s in making previously impossible tasks feasible. For example, modern AI-powered vision systems enable robots to track and manage inventory more accurately than humans ever could.

Advanced automation allows warehouses to store more products in smaller footprints, reducing overhead costs and improving logistics efficiency. These innovations wouldn’t be possible if we insisted on designing robots to work like humans rather than working from a blank slate and letting form follow function.

At Mytra, we focus on creating robotics that make material handling and storage dramatically more efficient. Our technology isn’t built to replace humans—it’s built to augment human capabilities and optimize workflows that were previously constrained by manual labor.

The future of robotics isn’t about waiting for humanoids to develop enough to replace workers decades from now; it’s about solving today’s problems with the best tools available.

Rethink the future of robotics

As automation continues to reshape industries, the most successful robots will be those that break free from the constraints of human form and instead focus on solving real-world challenges with the right design. Just as evolution rewards adaptability and function, robotics should follow the same principles—creating purpose-built systems that maximize efficiency, scalability, and reliability.

The future of robotics lies in engineering solutions that work now, not decades from now. The warehouses of tomorrow won’t be run by human-shaped robots; they’ll be powered by automation that’s purpose-built for the task at hand and makes the impossible possible.

About the author

About the author

Ahmad Baitalmal is co-founder and chief technology officer of South San Francisco-based Mytra. He has more than 25 years of experience leading the development of large-scale enterprise systems at companies such as Tesla and Rivian.

The post Why the future of robotics isn’t necessarily humanoid appeared first on The Robot Report.