Figure AI said it’s moving the manufacturing of its humanoids in-house to control the build process and quality.

The post Figure AI unveils BotQ high-volume humanoid manufacturing facility appeared first on The Robot Report.

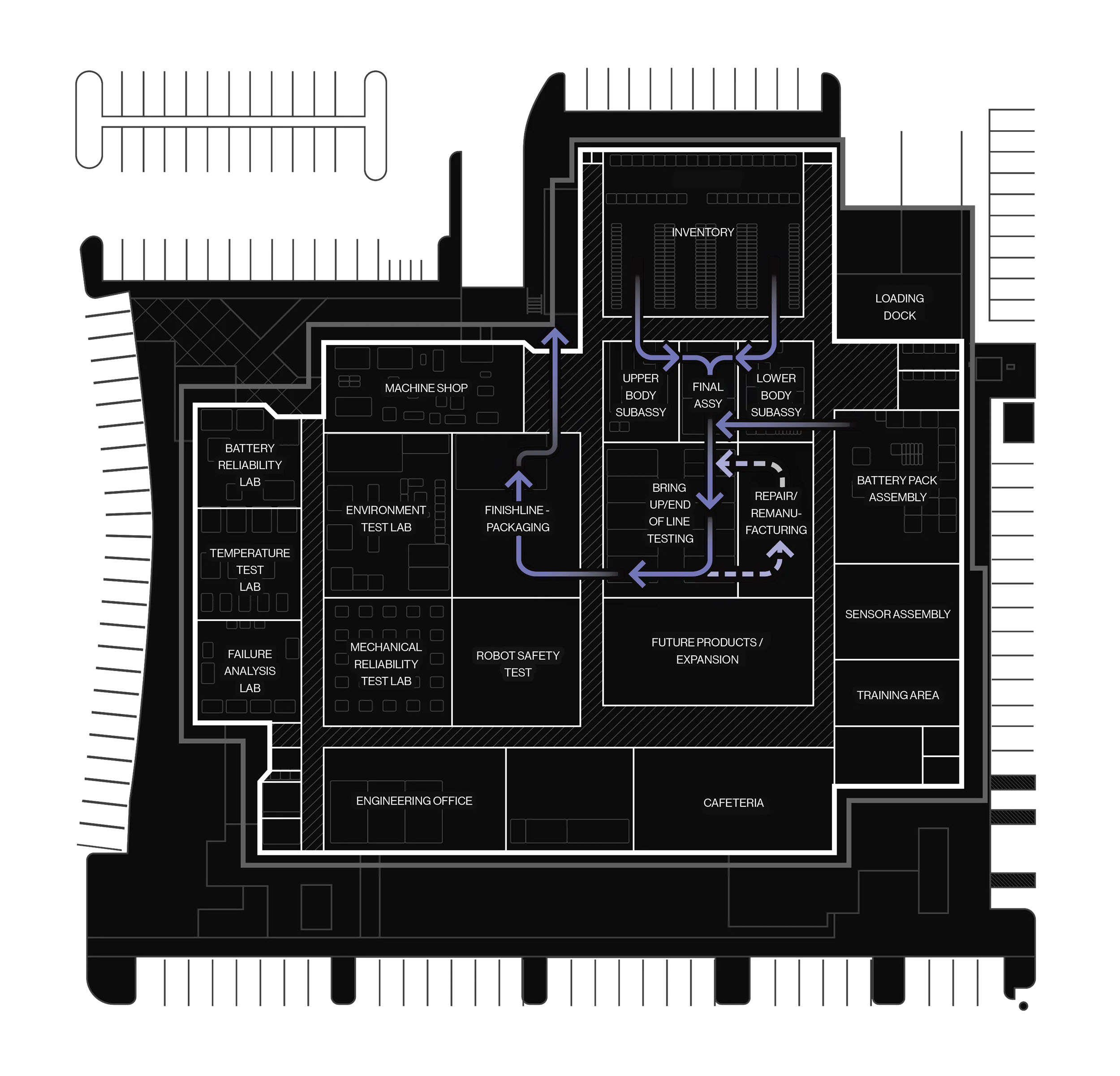

Humanoid robots have been slowly making their way into the workforce. However, one question remains unanswered: How will robotics companies make these complex systems at scale? Figure AI Inc. last week introduced BotQ, its new high-volume factory for humanoids. The company said BotQ’s first-generation production line will be capable of manufacturing up to 12,000 robots per year.

Figure AI said is bringing its manufacturing operations in-house to control the build process and quality. The company said this will also help guarantee that it delivers high-functioning robots to the market.

San Jose, Calif.-based Figure said it has spent the past eight months building an efficient and scalable manufacturing process from the ground up. It said it also spent the past six months creating a foundation to support volume manufacturing with software including manufacturing execution system (MES), product lifecycle management (PLM), enterprise resource planning (ERP), and warehouse management system (WMS).

Eventually, Figure said it will use humanoid robots in its manufacturing process to build other humanoids. As more robots work on production lines, the company said it will be able to increase its capacity. Figure expects to start later this year.

In the process of retooling its robot architecture, Figure started two new teams, a safety team, and a reliability team. In addition, the company said it is increasing its focus on on robot reliability.

The reliability team at BotQ is in charge of running highly accelerated lifecycle tests. These will help the company understand the lifespan of its robot.

The reliability team needs specialized equipment, including high-temperature ovens, dedicated actuator testers, and failure analysis equipment to understand root cause failures. Using this data, Figure said it can inform the robot designers of improvements needed to ensure its reliability metrics are met.

Figure AI announced in late 2024 that its robots are moving development and trials to commercial use. The company has delivered its Figure 02 system to a paying customer.

Figure AI won a 2024 RBR50 award for its rapid pace of innovation. Since emerging from stealth in January 2023, the company has iterated on its humanoid, tested its robot on a production line, and delivered systems to a paying customer.

Figure AI designs for high production rates

After building and internally manufacturing Figure 02, the Figure team recorded and analyzed cycle times for every process, from part fabrication to final assembly. It found the largest driver of assembly time started at the root: part count and manufacturing processes.

Figure originally designed Figure 02 as a prototype. This meant that it used high complexity, tight tolerance, and slow computer numerical control (CNC) machining processes. CNC from billet is a great process for prototyping and holds value for high-tolerance components. However, it does not scale well when trying to drastically reduce both part costs and time to make components.

In addition, Figure said in a blog post that it has worked to reduce its part count. It takes time to join two parts together, so the company emphasized combining many parts into one to reduce cycle time.

All of these considerations went into Figure’s next-generation robot, Figure 03. This robot is the company’s production robot built for affordability and high-volume manufacturing.

To achieve high production rates, Figure switched to tooled processes such as injection molding, diecasting, metal injection molding, and stamping. The company claimed they enabled it to save thousands of hours on manufacturing.

Figure said parts that previously spent over a week on a CNC machine can now be manufactured in under 20 seconds with complex steel molds. While switching to these processes comes with a high capital cost, the company said it expects a rapid return on investment (ROI) when considering its robot volumes for 2025 and beyond.

Figure invests in its supply chain

Unlike industrial automation, humanoid robots do not yet have well-established supply chains with various tiers of manufacturers building a system’s modules. Figure said this led it to design almost the entire robot from scratch. This includes the actuators, motors, sensors, battery pack, and electronics.

Figure said the lack of a mature supply chain has been one of the biggest hurdles it has faced when defining where and how parts would be made. So, it decided to focus heavily on the assembly of its core technology: actuators, hands, and batteries. The company can also call on outside vendors as needed to manufacture piece parts.

In addition, the company hired a team of global supply managers to help form strong partnerships with vendors who have the expertise to produce its complex components. Figure 03 said it has more than three-dozen commodities, many of which require unique processes such as motor winding, flexible OLED screens, or precise optical designs.

Figure selected all of its external partners to be able to scale with it. The company claimed that its supply chain can easily scale to 100,000 robots or 3 million actuators in the next four years.

Figure decides where to automate

After securing its supply chain, Figure needed to build up its manufacturing team and infrastructure. The company said it hired experts in designing production lines, optimizing them, and understanding how to optimize the process of turning materials into products.

Figure explained that its manufacturing engineers are responsible for breaking the robot assembly up into sub-stations, selecting the proper tools to join the parts together, designing and procuring fixtures for the assembly line, and understanding how to test the parts as they rapidly turn into a robot. The engineers also provide design-change feedback to the company’s mechanical, electrical, and software teams to decrease production cycle time.

One key aspect of its new product manufacturing is understanding which operations on the production line should be automated and which should be manual. Historically, humanoid robots have been built in low volumes, and automation has been rare. Figure has chosen in the short term to automate key elements of the process by looking at metrics such as quality and speed.

An example of automation for quality is the automated grease-dispensing station for its motor gearboxes. The company said it can control the location and volume of the gearbox grease far more accurately with an automated tool than with a manual grease gun.

An example of automation for speed is Figure’s cell test and load station. Here, a robot is far faster than a human at picking up, scanning, and testing every battery cell before assembly into the battery pack.

Creating the infrastructure to allow robots to build robots

To stand up a successful factory, Figure AI added new tools to its development process. It said the MES is the backbone of its manufacturing operation, and the company is building it in-house.

The MES integrates all aspects of production into a single, real-time digital ecosystem. From tracking parts through the supply chain to monitoring assembly efficiency and ensuring stringent quality control, Figure said the MES allows it to operate at peak efficiency.

Figure said its MES integrates with its Internet of Things (IoT) devices. This allows it to monitor process flow, track genealogy, and provide a digital database of all the test data related to every component in the robot.

The company added that BotQ will integrate its humanoids into its assembly lines. With this month’s introduction of the Helix modal, Figure said it can use its own robots to assemble key components on its production line.

The humanoids could act as material handlers, moving goods between different stations without needing to install bulky and inflexible conveyor systems.

The combination of AI-driven automation and human oversight allows for a hybrid workforce that maximizes speed, precision, and adaptability, said Figure. The use of robots to build more robots will accelerate production timelines while minimizing human intervention in repetitive tasks, the company said.

At the 2025 Robotics Summit & Expo in Boston on April 30 and May 1, sessions will include “The State of Humanoids” and “Redesigning Atlas: Boston Dynamics on the Future of Humanoids.”

Register now so you don’t miss out!

The post Figure AI unveils BotQ high-volume humanoid manufacturing facility appeared first on The Robot Report.