A new video from Boston Dynamics takes us behind the scenes of how it’s training the new Atlas humanoid to tackle its first task: auto parts sequencing.

The post Behind the scenes: Boston Dynamics’ Atlas humanoid learns to sequence auto parts appeared first on The Robot Report.

Boston Dynamics released a new video of the electric Atlas humanoid. The video shows behind-the-scenes snippets of the Atlas engineering team and the robot in various states of assembly and repair. It’s a refreshing look at the complex systems that make up a humanoid robot, and it’s also an honest look under the hood at a time when many companies are guarded about the IP within their robots.

Aaron Saunders, chief technology officer at Boston Dynamics, will deliver the opening keynote at Robotics Summit & Expo 2025, where he will unpack the new, electric Atlas humanoid and share insights from being at the forefront of humanoid development for years. This keynote will explore the challenges and opportunities of building humanoids for real-world applications, offering a behind-the-scenes look at how Boston Dynamics continues to innovate and push the limit of robotics.

The new video from previews many of the topics Aaron is likely to cover during his keynote. Here’s what I found interesting in it.

As a controls engineer, the first thing that I always pay close attention to is the motion of individual axes. In the video, you’ll notice Atlas isn’t always super stable when lifting, and manipulating heavy objects into and out of the placement locations. Watch the video at 3:06, and you’ll see that the motion control in the spine has to dynamically react to disturbances from the forces through the arms and shoulders during part placement.

Unlike the hydraulic version of Atlas, which was able to provide joint stiffness through hydraulic pressure, the electric motors of the new Atlas all have to servo dynamically to retain rigid body control. I find it fascinating to watch the entire system function to achieve a specific goal.

In the video, Scott Kuindersma, senior director of robotics research at Boston Dynamics, describes the challenges Boston Dynamics had with the hydraulic Atlas, and how the new, electric platform improves on these issues. “Our old lab used to have a thin coat of oil on it at all times,” Kuindersma said in reference to the hydraulic version of Atlas.

Boston Dynamics is now building its own actuators, a common strategy for modern humanoid manufacturers that’s also shared by competitors Apptronik and Figure.

Atlas leveraging training data

Boston Dynamics brings a vast wealth of experience in object manipulation. The company had an earlier start in the training of AI models via simulation. The analogy here is in the lifetime of learning that humans have in controlling their bodies, humanoids have a similar hurdle to achieve a level of functional control in completing even the simplest of tasks.

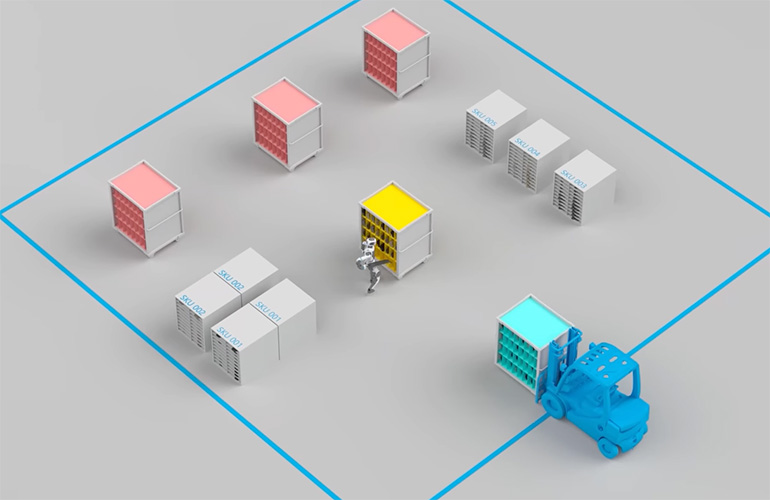

Boston Dynamics is training new AI models that will provide the intelligence to Atlas humanoid, enabling it to autonomously sequence parts for auto assembly plants. | Credit: Boston Dynamics

The second half of the video looks at the complexity of sequencing tasks for the robot. For humanoids to be useful at work, they need an understanding of the world around them, and how to break down task requests into manageable subtasks. Boston Dynamics is looking at sequencing concepts, and examining the thousands and thousands of parts that go into a vehicle, for example, and how to order those parts for assembly.

In the video, Atlas demonstrates its ability to sequence a parts cart given a description of the end state, along with a description of where to find the parts.

There is still a lot of work to be done, but it’s amazing to see the state of the art today and how quickly the capabilities and functionality of humanoids are evolving.

Humanoids at Robotics Summit & Expo

Humanoids will be prominent at the Robotics Summit & Expo, which runs from April 30 to May 1 in Boston and is produced by The Robot Report.

In addition to Saunders’ opening keynote, the first day of the event will feature a panel on the state of humanoids with Pras Velagapudi, chief technology officer at Agility Robotics; Aaron Prather, director of robotics and autonomous systems at ASTM International; and Al Makke, director of engineering at Schaeffler. They will explore the technical and business challenges shaping the development of humanoids. The panel will also share insights from early deployments, the ongoing efforts to establish safety standards, and what’s on the horizon.

Unitree will be discussing the development of its humanoids on Day 2 of the event and will be demoing the G1 humanoid in booth 652. Westwood Robotics, which spun out of UCLA, will have the latest version of its THEMIS humanoid in booth 650. Both humanoids will be interacting with attendees in various networking activities, too.

PSYONIC will also be discussing and demoing (booth 750) its advanced bionic hands that it’s developing in part for humanoids. Founder Aadeel Akhtar is giving the closing keynote of the event. These are just a few of the ways attendees will learn about humanoids at the event.

The Robotics Summit & Expo will bring together more than 5,000 developers focused on building robots for a variety of commercial industries. Attendees can gain insights into the latest enabling technologies, engineering best practices, and emerging trends.

The show will feature over 200 exhibitors, 70-plus speakers on stage, and more than 10 hours of dedicated networking time. It will also include a Women in Robotics Breakfast, a career fair, startup showcase, and more. Returning to the show are the RBR50 Pavilion and RBR50 Awards Dinner, which will honor the winners of the annual RBR50 Robotics Innovation Awards.

The post Behind the scenes: Boston Dynamics’ Atlas humanoid learns to sequence auto parts appeared first on The Robot Report.