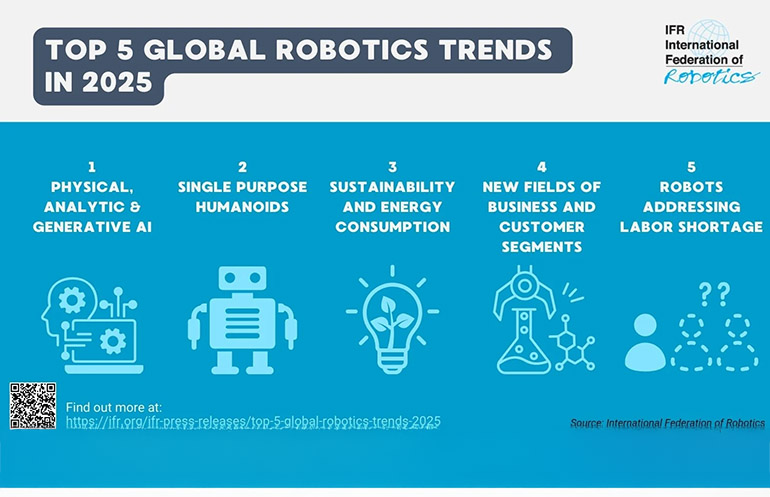

The International Federation of Robotics expects AI, humanoids, and sustainability to be top areas for robotics in 2025.

The post IFR predicts top 5 global robotics trends for 2025 appeared first on The Robot Report.

Source: IFR

The global market value of industrial robot installations has reached an all-time high of $16.5 billion (U.S.), according to the International Federation of Robotics, or IFR. Future demand will be driven by a number of technological innovations, market forces, and new fields of business, it predicted.

Sales of professional service robots, including warehouse systems, have increased by 30% worldwide, reported the Frankfurt, Germany-based organization in October 2024. Similarly, 4 million industrial robots are operating in factories worldwide, doubling industrial robot density, according to the IFR.

Last year, the IFR predicted more AI and machine learning, collaborative robots in new applications, increasing mobile manipulation, digital twins to optimize performance, and progress in humanoid robots. Today, it shared its forecast for the top five robotics industry trends for 2025.

1. Analytical, generative, and physical AI to aid robots

The trend towards artificial intelligence in robotics is growing, said the IFR. By using diverse AI technologies, robotics can perform a wide range of tasks more efficiently.

Analytical AI enables robots to process and analyze large amounts of data collected by their sensors. This helps to manage variability and unpredictability in their external environments, in high mix/low-volume production, and in public environments.

For example, robots equipped with vision systems can analyze past tasks to identify patterns and optimize their operations for greater accuracy and speed, the organization said.

Robot and chip manufacturers are investing in the development of dedicated hardware and software to simulate real-world environments. This so-called physical AI is intended to enable robots to train themselves in virtual environments and operate by experience rather than programming.

Generative AI projects aim to create a “ChatGPT moment” for physical AI, noted the IFR. This AI-driven robotics simulation technology could advance in traditional industrial environments as well as in service robotics applications.

2. Humanoids reach for potential markets

Robots in the shape of human bodies have received a lot of media attention. The vision is that such robots will become general-purpose tools that can load a dishwasher on their own and work on an assembly line elsewhere. Numerous startups are working on humanoid general-purpose robots.

However, manufacturers are focusing on humanoids performing single-purpose tasks only. Most of these projects are being carried out in the automotive industry, which has played a key role in pioneering robot applications throughout the history of industrial robotics, as well as in the warehousing sector.

“From today’s perspective, however, it remains to be seen whether humanoid robots can represent an economically viable and scalable business case for industrial applications, especially when compared to existing solutions,” said the IFR. “Nevertheless, there are many applications that could inherently benefit from the humanoid form and therefore offer market potential for robotics, [such as in] in logistics and warehousing.”

Register today to save 40% on conference passes!

3. Sustainability still a priority

Compliance with the UN’s environmental sustainability goals and corresponding regulations around the world is becoming an important requirement for inclusion on supplier whitelists. Robots play a key role in helping manufacturers achieve these sustainability goals, noted the IFR.

In general, their ability to perform tasks with high precision reduces material waste and improves the output-input ratio of a manufacturing process. These automated systems can ensure consistent quality, which is essential for products designed to have long lifespans and minimal maintenance.

In the production of green energy technologies such as solar panels, batteries for electric cars, or recycling equipment, robots are critical to cost-effective production. They enable manufacturers to rapidly scale up production to meet growing demand without compromising quality or sustainability.

At the same time, technology is being improved to make the robots themselves more energy-efficient. For example, the lightweight construction of moving robot components reduces their energy consumption. Different levels of sleep mode can put hardware in an energy-saving parking position.

The IFR also cited advances in gripper technology using bionics to achieve high grip strength with minimal energy consumption.

4. Robots to open new fields of business

The general manufacturing industry still has a lot of potential to add automation, said the IFR. Most manufacturers are small and midsize enterprises (SMEs). The adoption of industrial robots by SMEs is still hampered by high initial investment and total cost of ownership.

Robotics-as-a-service (RaaS) business models allow enterprises to benefit from automation with no fixed capital involved. RaaS providers specializing in specific industries or applications can offer sophisticated solutions quickly, the IFR said.

In addition, low-cost robotics offers systems for potential customers that may find a high-performance robot to be more than they need. Many applications have low requirements in terms of precision, payload, and service life. Low-cost robotics addresses this new “good enough” segment.

New customer segments beyond manufacturing include construction, laboratory automation, and warehousing.

Demand across all industries is being driven by recent crises such as the COVID-19 pandemic, geopolitical tensions, and supply chain challenges. They have increased political awareness of the strategic need for domestic production capacity, acknowledged the IFR. Automation allows manufacturers to nearshore production without sacrificing cost efficiency, it said.

An ABB YuMi manipulator at Karolinska Hospital is an example of expanding robotics applications. Source: IFR

5. Robots address labor shortages

The global manufacturing sector continues to suffer from labor shortages, according to the International Labour Organization (ILO). One of the main drivers is demographic change, which is already burdening labor markets in leading economies such as the U.S., Japan, China, the Republic of Korea, or Germany. Although the impact varies from country to country, the cumulative effect on the supply chain is a concern almost everywhere.

The use of robotics can significantly reduce the impact of labor shortages on manufacturing, the IFR asserted. By automating dirty, dull, dangerous or delicate tasks, human workers can focus on more interesting and higher-value tasks, it said.

Robots can perform tedious tasks such as visual quality inspection, hazardous painting, or heavy lifting. Technological innovations in robotics such as ease of use, collaborative robots or mobile manipulators help to fill gaps when and where needed.

The post IFR predicts top 5 global robotics trends for 2025 appeared first on The Robot Report.

Source: IFR

The global market value of industrial robot installations has reached an all-time high of $16.5 billion (U.S.), according to the International Federation of Robotics, or IFR. Future demand will be driven by a number of technological innovations, market forces, and new fields of business, it predicted.

Sales of professional service robots, including warehouse systems, have increased by 30% worldwide, reported the Frankfurt, Germany-based organization in October 2024. Similarly, 4 million industrial robots are operating in factories worldwide, doubling industrial robot density, according to the IFR.

Last year, the IFR predicted more AI and machine learning, collaborative robots in new applications, increasing mobile manipulation, digital twins to optimize performance, and progress in humanoid robots. Today, it shared its forecast for the top five robotics industry trends for 2025.

1. Analytical, generative, and physical AI to aid robots

The trend towards artificial intelligence in robotics is growing, said the IFR. By using diverse AI technologies, robotics can perform a wide range of tasks more efficiently.

Analytical AI enables robots to process and analyze large amounts of data collected by their sensors. This helps to manage variability and unpredictability in their external environments, in high mix/low-volume production, and in public environments.

For example, robots equipped with vision systems can analyze past tasks to identify patterns and optimize their operations for greater accuracy and speed, the organization said.

Robot and chip manufacturers are investing in the development of dedicated hardware and software to simulate real-world environments. This so-called physical AI is intended to enable robots to train themselves in virtual environments and operate by experience rather than programming.

Generative AI projects aim to create a “ChatGPT moment” for physical AI, noted the IFR. This AI-driven robotics simulation technology could advance in traditional industrial environments as well as in service robotics applications.

2. Humanoids reach for potential markets

Robots in the shape of human bodies have received a lot of media attention. The vision is that such robots will become general-purpose tools that can load a dishwasher on their own and work on an assembly line elsewhere. Numerous startups are working on humanoid general-purpose robots.

However, manufacturers are focusing on humanoids performing single-purpose tasks only. Most of these projects are being carried out in the automotive industry, which has played a key role in pioneering robot applications throughout the history of industrial robotics, as well as in the warehousing sector.

“From today’s perspective, however, it remains to be seen whether humanoid robots can represent an economically viable and scalable business case for industrial applications, especially when compared to existing solutions,” said the IFR. “Nevertheless, there are many applications that could inherently benefit from the humanoid form and therefore offer market potential for robotics, [such as in] in logistics and warehousing.”

Register today to save 40% on conference passes!

3. Sustainability still a priority

Compliance with the UN’s environmental sustainability goals and corresponding regulations around the world is becoming an important requirement for inclusion on supplier whitelists. Robots play a key role in helping manufacturers achieve these sustainability goals, noted the IFR.

In general, their ability to perform tasks with high precision reduces material waste and improves the output-input ratio of a manufacturing process. These automated systems can ensure consistent quality, which is essential for products designed to have long lifespans and minimal maintenance.

In the production of green energy technologies such as solar panels, batteries for electric cars, or recycling equipment, robots are critical to cost-effective production. They enable manufacturers to rapidly scale up production to meet growing demand without compromising quality or sustainability.

At the same time, technology is being improved to make the robots themselves more energy-efficient. For example, the lightweight construction of moving robot components reduces their energy consumption. Different levels of sleep mode can put hardware in an energy-saving parking position.

The IFR also cited advances in gripper technology using bionics to achieve high grip strength with minimal energy consumption.

4. Robots to open new fields of business

The general manufacturing industry still has a lot of potential to add automation, said the IFR. Most manufacturers are small and midsize enterprises (SMEs). The adoption of industrial robots by SMEs is still hampered by high initial investment and total cost of ownership.

Robotics-as-a-service (RaaS) business models allow enterprises to benefit from automation with no fixed capital involved. RaaS providers specializing in specific industries or applications can offer sophisticated solutions quickly, the IFR said.

In addition, low-cost robotics offers systems for potential customers that may find a high-performance robot to be more than they need. Many applications have low requirements in terms of precision, payload, and service life. Low-cost robotics addresses this new “good enough” segment.

New customer segments beyond manufacturing include construction, laboratory automation, and warehousing.

Demand across all industries is being driven by recent crises such as the COVID-19 pandemic, geopolitical tensions, and supply chain challenges. They have increased political awareness of the strategic need for domestic production capacity, acknowledged the IFR. Automation allows manufacturers to nearshore production without sacrificing cost efficiency, it said.

An ABB YuMi manipulator at Karolinska Hospital is an example of expanding robotics applications. Source: IFR

5. Robots address labor shortages

The global manufacturing sector continues to suffer from labor shortages, according to the International Labour Organization (ILO). One of the main drivers is demographic change, which is already burdening labor markets in leading economies such as the U.S., Japan, China, the Republic of Korea, or Germany. Although the impact varies from country to country, the cumulative effect on the supply chain is a concern almost everywhere.

The use of robotics can significantly reduce the impact of labor shortages on manufacturing, the IFR asserted. By automating dirty, dull, dangerous or delicate tasks, human workers can focus on more interesting and higher-value tasks, it said.

Robots can perform tedious tasks such as visual quality inspection, hazardous painting, or heavy lifting. Technological innovations in robotics such as ease of use, collaborative robots or mobile manipulators help to fill gaps when and where needed.

The post IFR predicts top 5 global robotics trends for 2025 appeared first on The Robot Report.